SolderlessPCB: Empowering Electronic Component Reuse in PCB Prototyping with Detachable 3D Printed Housings

This project explores an alternative approach to traditional PCB prototyping, aimed at promoting the reuse of still-functional SMD components.

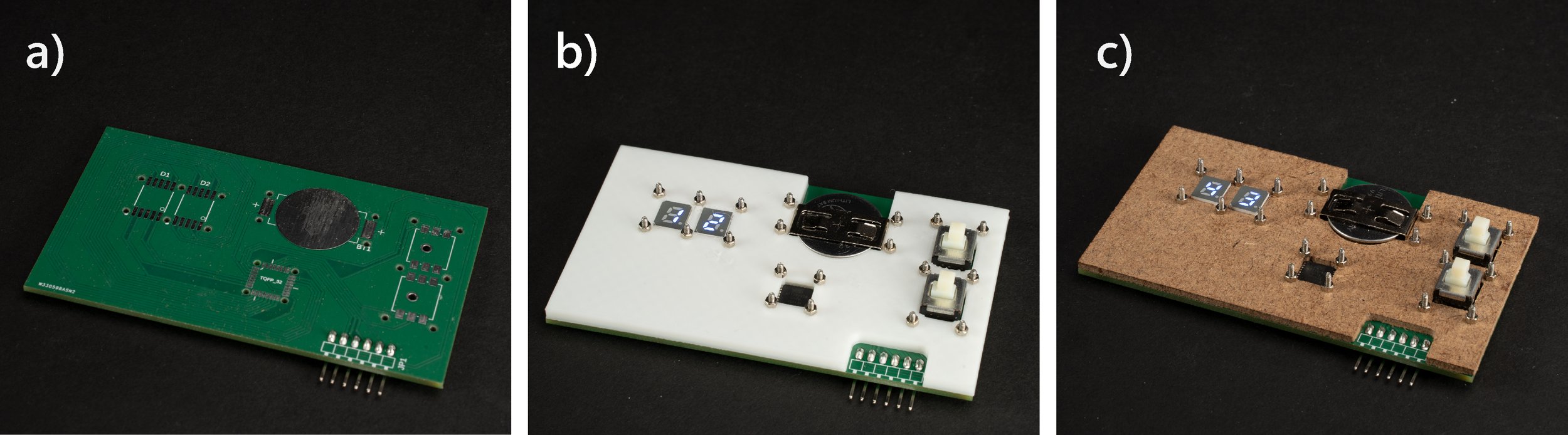

The key to our idea is a set of 3D-printable housings that can mechanically mount SMD components onto custom PCBs. This eliminates the need for soldering and desoldering during PCB assembly, thereby allowing designers and engineers the flexibility to interchange SMD components similarly to how they would with through-hole components in breadboard prototyping. This approach enables the reuse or replacement of SMD components, while also allowing the exploration of the comparably small form factor of custom PCBs. We call our prototyping technique.

We detail the key design considerations and the fabrication method for the 3D-printable housings. We then present a series of experiments on resistance, impedance reproducibility, and high-frequency signal loss in circuits made with SolderlessPCB. These experiments characterize the electrical performance and stability of our approach.

To contextualize SolderlessPCB, we present two scenarios in which SolderlessPCB can encourage the reuse of electronic components during prototyping, accompanied by three additional examples: a mug heater, a mini game console with an OLED display, and an FTDI code uploading module that showcase the applicability of our method.

We conclude with a discussion on the limitations of our approach and our thoughts on future research directions.

Created by:

Zeyu Yan, Jiasheng Li, Zining Zhang, Huaishu Peng

Publications:

🏆Special Recognition for Sustainable Practices (Winner of Research with Potential for Sustainable Impact)